What does it take to succeed in Print and how to pivot production in a Pandemic

.png?lang=en-GB&width=790&height=450&ext=.png)

What does it take to succeed in print? Debbie Mckeegan, FESPA’s Textile Ambassador talks to Nathan Swinson-Bullough, Director of Image Co LTD and FESPA UK board member.

Innovation, hard work and an inherent “can do” approach is never in short supply at Image co, where a dynamic team are driving their print business forward even in the current pandemic. Image co are a wide format digital print service, they offer a diverse suite of products including POS, Textiles and Interior Wallcoverings. With a global reach, they supply wide format graphics, and Textiles to the Retail sector and clients worldwide from their impressive manufacturing plant in Leeds, UK.

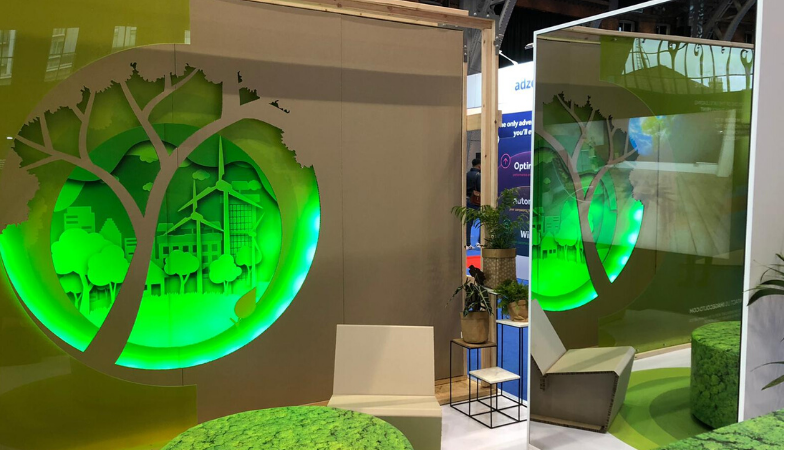

Caption: Digital City Awards – Sustainable display “We’re proud to say almost all 100% recyclable and made from recycled materials”. Credit: Image Co LTD

As we speak, we are in the midst of an unprecedented pandemic, one that will without doubt change the future for us all, with both positive and negative aspects for commerce across the world.

Tasked with the momentous challenge of the disruptive impact of the corona virus, Nathan and his management team acted fast to protect the business. Furloughing 20 staff and keeping on a skeleton crew for minimal production, or worse-case scenario no production.

What happened next is a tribute to their businesses flexible business model and the power of digital manufacturing technologies. As the pandemic has developed over the last couple of weeks the requirement for instore graphics has taken on an urgent necessity to protect lives. Clear display signage for social distancing measures, wayfinding, and even protective masks are in demand, and as we emerge from the current lock-down these products that have brought a much-needed opportunity in a time of distress for any businesses, and offer a window of opportunity for Image Co.

.jpg?lang=en-GB)

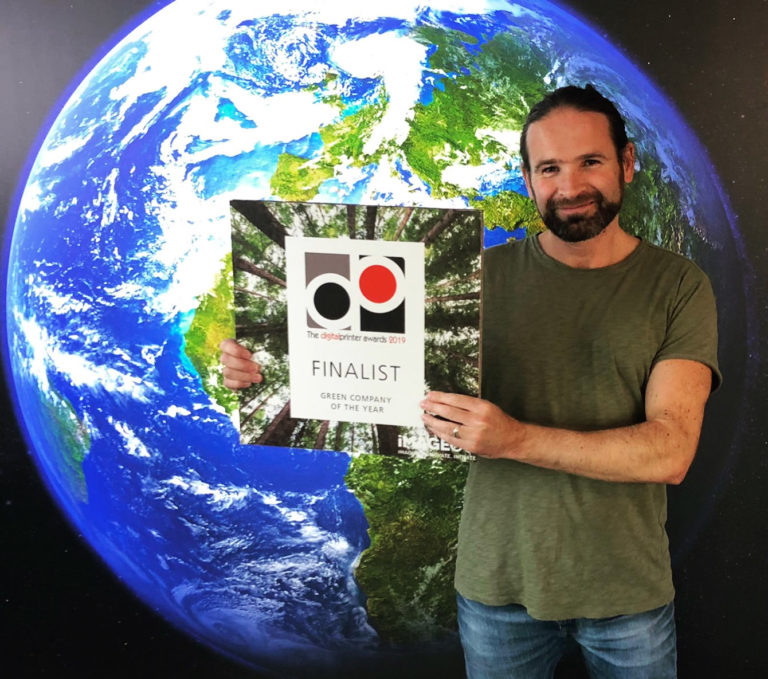

Caption: Nathan Swinson-Bullough of Image Co LTD attributes the company’s success to a dynamic team, hard work and constant innovation. Credit: Image Co LTD.

Image co ltd, was founded in 2000, and has evolved alongside the digital print space to become a successful supplier in a crowded marketplace. Nathan attributes their success to a dynamic, hardworking team and a never-ending quest for applied innovation, keeping up with the latest technology and the valuable investment in a powerful marketing strategy.

Marketing has become an increasingly tangible asset for the print industry and one that must not be ignored. Branding, strategy, and a flexible, state of the art, smart factory are essential factors of Image Co’s successful growth. So too is Nathans drive, intuition and imagination.

Image co has invested in both 3D modeling software, and the Caldera software suite to guarantee accurate, speedy design for pre-press and production, and importantly strong colour management across the manufacturing workflow. In harness their progress towards industry 4.o is twinned with technologies from Durst, HP, EFI-Vutec and Zund. Image Co’s arsenal of digital print technologies offers product diversity across multiple surfaces and the ability to pivot production (even in a pandemic) to meet the demand of their clients.

The print and textile communities across the globe have rallied at great speed to help, support and meet the demands now faced by the health system, NHS, and healthcare workers worldwide. Image co have made a substantial, voluntary contribution to the demand, supporting for their local community in donating masks, signage and essential PPE equipment and protective screens wherever possible.

Even before the pandemic, Nathan recognized that the importance of sustainable production must be addressed. Sourcing new substrates and incentivizing clients to switch to green eco-substrates has also become a personal mission for Nathan. Image Co now offer a green alternative for most of their media options and look to expand their range further as the availability of substrates improves. But that’s not all, one of the biggest factors of sustainable production is energy, and whilst digital technologies are by nature energy efficient, Image Co have gone further still by installing an energy saving system that reduces the factories consumption further.

Caption: Image Co LTD gained recognition for their green ethos when shortlisted for Green Company of the Year at the Digital Printer Awards. Credit: Image Co Ltd.

Events as we know are often a hotspot for waste, and at the recent Digital City exhibition Image Co displayed a sustainable stand design:

“We were very happy to show off our skills with a sustainable exhibition stand that was mainly made from Xanita, recycled wood and some green cast acrylic. We’re proud to say it’s almost all 100% recyclable and made from recycled materials. We call that a win-win.

Everything from our business cards to the chairs was made from sustainable materials.

The aim of the stand was to show you don’t need to rely on outdated environmentally detrimental materials, you can create an entire exhibition from our eco-product range. The cross-section backdrop for our stand was made from Xanita, a fully sustainable paper-based product. It also included an LED feature that showed off just how green we are, a fantastic collaboration between us and Applelec”.

It was a pleasure to talk with Nathan Swinson-Bullough, his honesty and energy to be admired by all. We wish Nathan and his team continued success as we face the challenge of COVID-19 and the drive towards sustainable manufacturing together.

You can listen to the Podcast recorded here.