The digital printing industry rallies together to battle COVID-19

.jpg?lang=en-GB&width=790&height=369&ext=.jpg)

The COVID-19 pandemic is holding many countries around the world in suspense. Digital printers help fight the virus, with 3D printing proving to be particularly useful.

Caption: Isinnova and FabLab Brescia developed the “Charlotte” valve, which can be used to convert a Decathlon schorchel mask into a makeshift ventilator. Photo: Isinnova

Northern Italy suffered terribly from COVID-19 and the immediate lack of ventilators is exacerbating the situation. That’s why Dr. Renato Favero, the former Head of the Brescia hospital, had the idea to build makeshift ventilators from diving masks. He partnered with Isinnova, a consulting firm in the industrial engineering sector. Both contacted Decathlon, the French sporting goods giant. Decathlon sells the Easybreath snorkel mask, which serves as the foundation of the ventilators. Decathlon immediately provided the CAD drawing of the snorkel mask. A valve was developed where the mask can be connected to ventilators commonly used in hospitals. The CAD data for the valve and the instructions was created and published within a few days.

Caption: 3D specialist Weerg made the valve “Charlotte” with an HP Multi Jet Fusion 5210 printer. Photo: Weerg

The valve can be produced by using any 3D printer. However, 3D printers designed for home use are typically very slow, that is why the Italian 3D start-up company, Weerg got involved. Founder Matteo Rigamonti commented: “We contacted Isinnova, and thanks to our HP Multi Jet Fusion 5210 printer, we were able to print some of the 500 required PA12 nylon valves. PA12 nylon is a material that can be used in healthcare.” Matteo further commented: “We have 50 quintals of nylon PA12 for 3D printing solutions that can help our country cope with this dramatic situation. Because of this we have sent e-mails to several healthcare companies who of course will only have to cover material costs.”

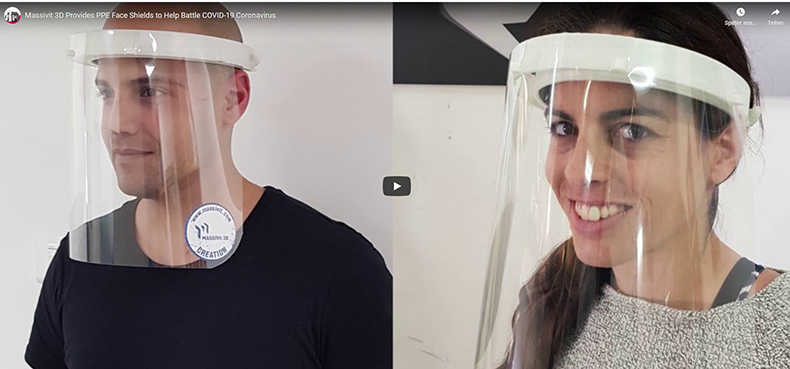

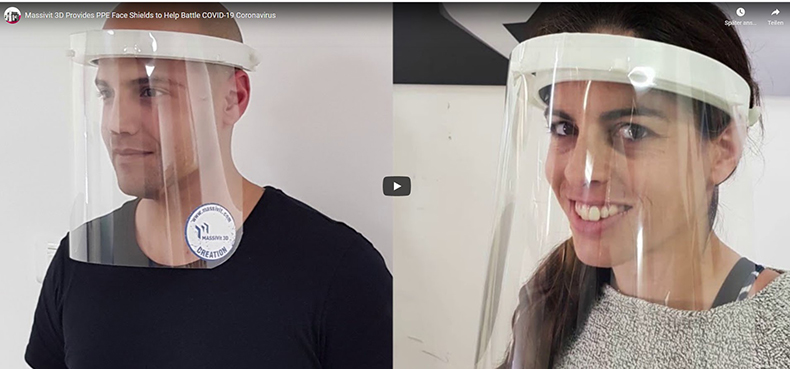

Face protection with Massivit printers

Caption: Massivit publishes a guide to building face shields using its 3D printers. Photo: Massivit.

In addition to a lack of ventilators, there is also a lack of protective equipment worldwide which is crucial for medical staff who need them to protect themselves. The Israeli manufacturer of 3D printers Massivit has provided its customers with a sample file as well as instructions for building high-quality face shields made of PE. The CAD file is based on a design by Twan Kerckhofs of Art Nzo, a Flemish 3D printer that works with Massivit printers. Due to the large size of the Massivit printers, the mounts for the face shields can be produced particularly quickly. Massivit has made the instructions available to all its global customers via their homepage and has also made a video about it.

Caption: Marabu Inks also manufactures disinfectants during the Corona crisis. Photo: Marabu

In addition, the production of Mara Disinfect is available on video. Marabu Inks now its new WHO-recipe disinfectant which can be used for both hand and surface disinfection. A large portion of the funds from the production of the disinfectant is donated to hospitals and similar medical facilities in the Ludwigsburg region.

Many digital printers have suffered massive losses as a result of the Coronavirus, as trade fairs have been cancelled and many shops are not open. The production of trade fairs and POS materials has therefore largely come to a standstill. With the construction of face shields made of acrylic as well as floor graphics and stickers to clarify the social distancing rules, a new business opportunity has become available. Foto Fabrics, for example, provides free information stickers for contactless payment to shops in the area.

Digital printers with experience in textiles and digital cutting are also producing masks. Masks for the mouth and nose can help curb transmission via droplet infection. According to its own data, the Essen-based brand specialists Weiss + more currently produce approximately 8,000 masks per day and also deliver packages for social institutions such as the Kinderherz Foundation.

Hope in difficult times

For the digital printing industry, the COVID crisis represents a serious cut that is likely to greatly change the face of the industry. However, the local and flexible production opportunities that are occurring in the factories are also a great help at a time when global supply chains are stalling. It is therefore quite possible that for some companies, completely new niches will open up in areas in the future.