Agfa Graphics releases PressTune and InkTune

Afgha Graphics announced the release of their PressTune and InkTune software to lower production costs. PressTune and InkTune are part of Afgha Graphics’ ECO³ offering and provides print houses control over all printing elements whilst simultaneously reducing production costs.

ECO³

PressTune and InkTune are key elements of Agfa Graphics’ ECO³ program. The design and creation of solutions based on hardware, software and consumable Agfa Graphics concentrates on economy, ecology and extra convenience (ECO³) to ensure prepress and printing operations cleaner, simpler to manage and more cost-effective. The ECO³ solutions push extra value to printing businesses.

InkTune: cost savings plus quality boosts

Building on grey component replacement (GCR) technology, InkTune substitutes CMY inks with black ink. InkTune is an intuitive software solution that is entirely integrated into the prepress workflow. It uses Agfa’s unique technology including Dynamic Ink Limit Control and Dynamic Device Link Generation to fully maximize ink reduction up to 30% whilst keeping colour fidelity. Reducing the ink saves significant costs and increases the overall production efficiency since the drying time is reduced. In addition, quality levels increase as rosette structures disappear and colour deviations become less visible.

Afga’s, Global Marketing Manager of Software Solutions, Erik Peters says: “InkTune removes the choice between the reduction of ink, time and drying powder and high-quality prints. Customers can attain all these benefits via the software’s built-in intelligent adjustment of ink consumption. InkTune enables them to reduce press setup times and the costs of all print-related resources which allows them to achieve the lowest total cost of ownership on the market. InkTune is easily set up and requires no additional investment in training or hardware.”

PressTune: a new benchmark in smart print process control

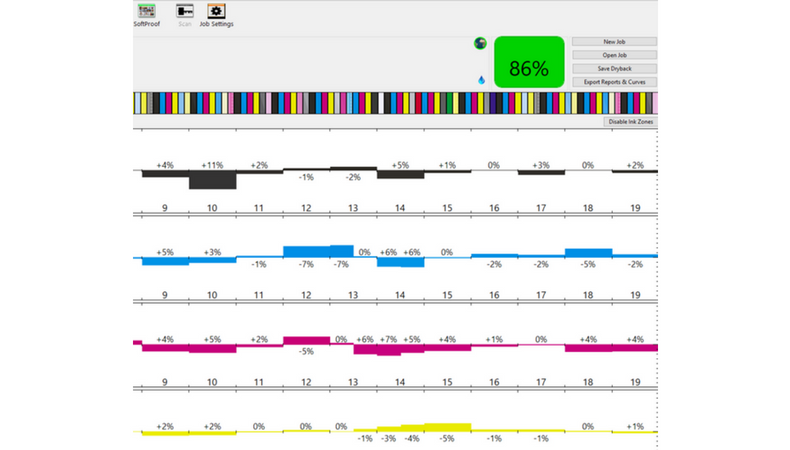

PressTune is a print production tool that drives consistency, productivity and can print exacting standards. Since the required print quality standard is attained faster via the dynamic ink density adjustment and a data-driven scoring mechanism that incorporates dry-back compensation. In addition the make-ready times are reduced by nearly 40% which leads to reduced waste.

By using intelligent analytics capabilities that are applied to print and colour data obtained from the press, PressTune reports in real time across printing technologies to every stakeholder for full transparency of the print production process. It provides issue identification and optimized press maintenance scheduling. Furthermore, PressTune’s easy-to-read dashboard makes it easy to generate print quality reports for brand owners in packaging and commercial print. It enables remote quality assurance.

Erik Peeters continues: “PressTune and InkTune offer huge cost savings by reducing the ink usage, increasing quality and by accelerating the production workflow. PressTune delivers InkTune with the seamless foundation to optimize ink consumption by delivering quality consistence. PressTune and InkTune are key to our ECO³ offering. They embody sustainable innovation that is focused on economy, ecology and extra convenience for the customer.”

Complementary solutions in action

Imprimeries et Editions Henry is a print house in in Montreuil-sur-Mer with a 120 year history who have worked recently with consultants from Agfa Graphics to enhance their print processes. The firm already has an Avalon system, Azura plates and Agfa Graphics’ Apogee workflow and now they have installed both PressTune and InkTune.

Marc Henry from Imprimeries et Editions says: “Both PressTune and InkTune have allowed us to get a higher consistency throughout our print run. Our make-ready times have been reduced, we use less paper and ink and we can also adapt printer calibration curves dependent on paper, print job or customer-specific demands. Agfa Graphics’ solutions have brought us a much easier way of working.”